Harvesting and utilising the vast amounts of data produced by modern aircraft – Part 2

Welcome to part two of our series on how to harness the huge amount of data that aircraft produce. As mentioned, some planes generate 20 Terabytes of engine data per hour and measure up to 400,000 parameters throughout the aircraft.

The benefits of collecting and analysing this data include improved safety, compliance, fuel efficiency, and customer experience, as well as lower maintenance costs and more streamlined fleet management. With that said, getting from the point of fitting sensors to aircraft and deriving valuable insights from the data gathered is a laborious endeavour – unless you have the right tools.

This article focuses on how to manage the overwhelming volumes of aircraft data and also takes a look at what may be possible in future thanks to new and advancing technologies.

How We Can Use Aircraft Data

The main advantage of aircraft data is that it allows us to be proactive in our approach to maintenance. Let’s have a brief recap on some of the example scenarios we mentioned in part one:

Aviation Data Management

Herein lies the challenge of collecting aircraft data – the endless Terabytes need to be aggregated, stored, structured, and made accessible to MRO operators using various types of devices; in other words, it needs to be made usable. In addition, the quality and security of the data must be handled.

When stored, data needs to be centralised and not siloed. Siloed data can lead to incorrect findings as the analysis is not performed based on the full picture; this could cause issues with airworthiness and compliance, leading to the grounding of aircraft as well as legal action.

It takes a lot of time and resources on a continuous basis to get the raw data into an organised format that provides a single source of truth. However, time is not a luxury that airlines and MRO operators have much of – the endless streams of data need to be processed quickly for each flight.

That’s why every airline, MRO or CAMO needs a solid data management strategy (an added benefit of which is avoiding potential data breaches).

A few things to consider include where to store the data and how much storage is necessary in order to meet the daily demands; and whether you have data scientists on-board that have the skillset to process the data correctly.

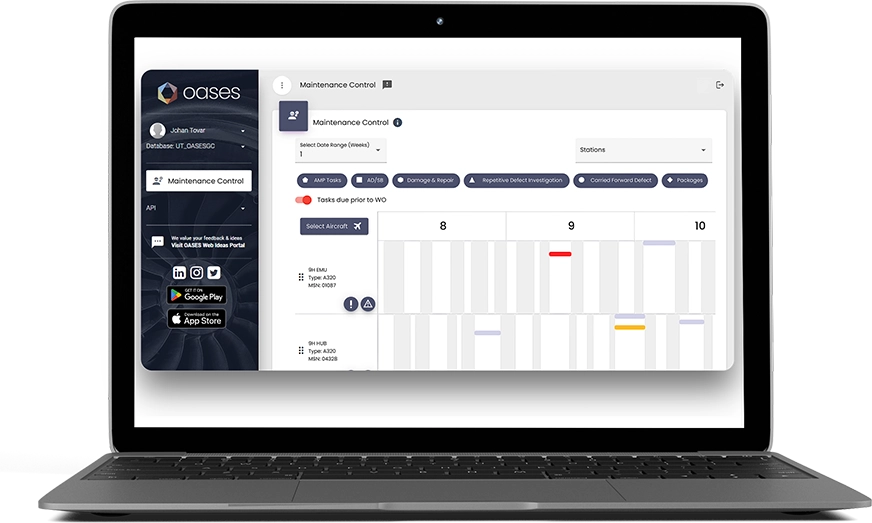

To make things much, much easier, cloud based MRO software such as OASES is designed to take the volumes of raw data from each flight and process it so that it’s usable and organised, and produces accurate insights.

The Future of Big Data in Aviation

The future implications of big data in aviation are vast and varied. As technology continues to evolve, the amount of data generated by aircraft will only continue to grow, which will create new opportunities and challenges. However, let’s focus on a couple of exciting new possibilities.

Digital Twins

Digital Twin technology is used in a range of industries. By collecting data from sensors, a virtual replica is created of the physical device in-question; from there, computational models are created in order to run simulations.

Some organisations are starting to use this for aircraft engines, such as Boeing and Rolls-Royce. During flight, data from the sensors is input into the twin in real-time. Various ‘what-if’ scenarios can therefore be tested on the twin which could not be safely tested on the real engine, providing insights that would not otherwise be possible. This can indicate various areas of improvement, including efficiency and reliability. As a result, the data can be used when designing and manufacturing engines.

Blockchain Technology

There are several key ways in which blockchain can improve MRO. First of all, it assists with data management – specifically, by verifying the accuracy of data. Since every record on the blockchain is immutable, the scope for falsified data will diminish, providing the ultimate transparency.

Another application of blockchain in aviation is in supply chain management. It will make it easier to track the movement of inventory, which is needed given the complexity involved in this industry.

Conclusion

The harnessing of big data is transforming the aviation industry. Operators can gain insights that were not possible in the past thanks to the placement of thousands of sensors around aircraft that continuously collect data during each flight.

The use of this data is enabling airlines to move from reactive to predictive maintenance, reducing costs and improving overall aircraft availability.

The challenge arises when it comes to data management. A great deal of processing is needed in order for data to be usable – it has to be aggregated, structured, centralised, and made accessible to all required personnel. It also needs to be secured and verified.

This is a monumental undertaking due to the continuous inflow of data, and failure to process it accurately can lead to flawed insights and legal consequences.

Thankfully, MRO software exists to carry out this processing so that MRO operators can focus on what matters most – taking action based on the insights produced.

Our software consists of 9 modules that take care of your MRO data, handling everything from materials management to warranty management to customs tracking, and much more.

To discover how it can ensure the continuing airworthiness of your fleet, contact us today to arrange a demo.

To learn more or book an OASES demo, contact us today

For organisations looking to ascend to new heights of operational excellence, contact us today to book a demo.