Due to the recent struggles in the industry, airlines have been seeking to reduce operational and maintenance costs, yet there is a fine line between reducing costs and putting safety at risk. The safe way to reduce costs comes down to using the right technologies – technologies that increase efficiency by automating the most time-consuming processes and establishing order.

As well as automation, predictive maintenance keeps you one step ahead, ready to address potential issues before safety is compromised. This proactive approach can reduce downtime, protect flight schedules, improve customer service, and ensure that aircraft are well-maintained and compliant with industry regulations.

Read on to discover more about how to maintain the fine balance between safety and profit in aviation MRO.

Key Elements of MRO Optimisation

Maintenance Planning and Control

Planning the maintenance of a fleet is a monumental undertaking with plenty of scope to lose time if adequate systems are not in place. Efficient planning and monitoring is the key to reducing costs resulting from inefficiencies, and MRO software makes it much easier to do so. Huge volumes of data are generated every flight; it’s vital to have the technical infrastructure in place to derive useful insights from it.

MRO systems should do following:

- Track work orders and performance

- Schedule maintenance on a proactive basis before any critical issues arise

- Automatically generate work orders

- Track individual maintenance tasks in granular detail

- Automatically generate documentation required for work orders

- Keep all associated documentation organised and accessible to authorised personnel

All routine tasks should be scheduled for planned time slots to ensure optimal service for the end customer, whether commercial passengers, or freight customers relying on the timely delivery of goods.

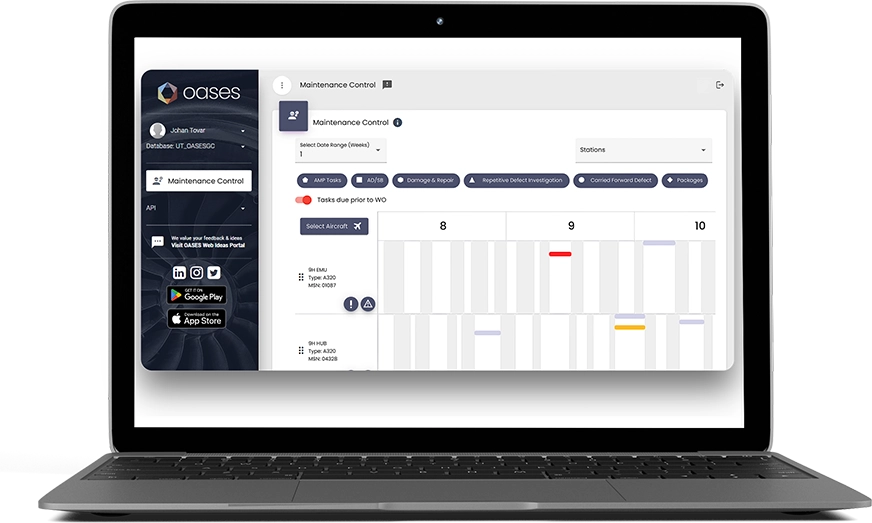

When unexpected occurrences disrupt these schedules, foresight is important. Your MRO system should show users the knock-on effects of short-notice schedule changes so that disruption can be minimised. Our Maintenance Control module does exactly that, giving users a visual oversight of all work orders.

Busy line maintenance schedules leave minimal room for error or delays, so personnel need to have high visibility of aircraft statuses at all times. The vast volumes of data generated with each flight also needs to be effectively managed in order to derive the greatest benefit. MRO software should automate the processing of this data.

Further streamlining is possible when planning and inventory modules are connected, allowing for automated material provisioning. The system can then reserve stock ahead of time.

Materials Management

Some of the most challenging aspects of inventory management include maintaining continuous visibility of stock, poor order management, and the use of manual documentation (and the errors it causes).

Materials management tools for MRO must be able to track the high volume of parts, components and other assets, minimise logistics costs, and automate the process for generating documentation. MRO software streamlines materials management in various ways, such as:

- Continuously and automatically monitoring stock levels, locations and histories

- Automatic shortage management

- Automating the generation of re-order or stock transfer reports

- Managing the tools required for maintenance tasks

- Automatically producing all required documentation

- Reducing the manual work required for invoicing

- Providing an audit trail for tracing all required information about all items within the system

Warranty Management

Warranty management is another admin-heavy area with great scope for automation. Users should be able to define rules within the system and, based on those rules, warranties should be automatically claimed on unserviceable parts that meet the warranty terms. In some cases, items meet more than one warranty term – manually keeping on top of complex criteria is a lot of work, and any system that can flag such cases reduces the time and effort involved in the decision making. Finally, by gathering data on claim outcomes, reports are generated to inform future warranty management practices.

Continuing Airworthiness

Monitoring the airworthiness of a fleet is a complex endeavour which requires thorough systematisation. The right software will connect all teams via a single source of truth, which is important for maintaining clear oversight and ensuring compliance. Frontline teams need to be able to track reliability issues, defects, trends and remedies, and engineers need to be able to respond to work orders in real-time if maximum efficiency is to be achieved.

The OASES Continuing Airworthiness module automatically collects comprehensive data on the condition of components and defects, generates detailed reports, and automatically raises a repetitive defect investigation if three events occur. This maximises the time that aircraft are in a condition for safe operation.

Final Thoughts

MRO operations are complex and intricate. Many organisations are still relying on manual, paper-based methods that are prone to errors and take up a great deal of time. MRO software standardises the process and provides oversight for managers, helping all parties access a single source of truth for the status of entire fleets.

By standardising processes such as overall fleet management, maintenance planning, and materials management, airlines can optimise the efficiency, accuracy, and reliability of their MRO operations – reducing costs yet ensuring maximum safety. In addition, proactive maintenance reduces downtime and prevents disruption, ensuring the best service for the end customer.

As well as all the above, our MRO software makes customs tracking more efficient, capturing data for every item that crosses a border, whether that’s incoming or outgoing shipments. It also streamlines commercial management processes such as generating quotations and handling labour charges, freight charges and other transactions. To discover how we can cut the waste from your MRO processes, contact us to book a demo today.