Aircraft generate a huge amount of data – and when left in its raw form, chaos is the result. Thankfully, we’re here to create order from chaos by managing your data in a way that provides maximum operational value.

What do we mean by value? Compliance, planning and monitoring MRO operations, and stepping away from paper-based inefficiencies and inaccuracies.

With our software, OASES, your entire organisation is joined, able to share information at the right time through a centralised platform.

OASES consists of a range of connected modules that you can tailor based on your organisation’s requirements. OASES Cloud, OASES API Gateway and OASES Insight are also vital components of the system.

In this two part series, we’ll guide you through the highlights of how our software improves maintenance operations. So, read on to discover how much value you can get from your data with the platform used by 130+ aviation customers in 55 countries.

OASES Modules

Planning

This module automates many tasks within your maintenance processes. First, it predicts when any maintenance tasks, modifications and defect limitations are due. Staff can then integrate these into work orders, after which the system automatically generates work package documentation and material pre-loads.

Every required maintenance task is tracked in the system. Users can define the type of task, labour time required, the relationships between tasks, and many other pertinent details.

What else does the module have to offer?

- Manufacturer job instructions: Instructions and their revisions are automatically imported and linked with the task. When the task is called to a work order, the instructions are automatically attached to the work card and printed, referencing the attachment in the narrative. The same automation is possible with other relevant documentation.

- Maintenance check packages: Tasks are aggregated into packages where needed. This can be scheduled into a work order in an instant.

- Access panels: For each task in the work order, access panels can be automatically derived. In addition, a range of control methods are available for managing them.

- Workpack production: A workpack is produced for each work order and can be distributed to the party that will be carrying out the maintenance (PDF or hard copy).

With every detail of every task for your entire fleet securely logged and trackable, you will never again need to worry about errors or lost information.

Continuing Airworthiness

Our solutions help airlines and MRO providers efficiently manage and track the maintenance records, inspections, and compliance requirements for each aircraft. It ensures that all maintenance tasks are performed in accordance with industry standards and regulatory mandates.

By maintaining comprehensive, accurate and up-to-date records, the software lets organisations demonstrate compliance during audits and inspections, ensuring the safety, reliability, and airworthiness of the aircraft they service.

A few highlights of the module are:

- Fleet level reliability statistics are represented graphically, for utilisation, in-service and maintenance defects, dispatch reliability, component removals and open defects. The user can define further defect classifications.

- Repetitive defect alerts

- Aircraft build

- Component tracking

The Continuing Airworthiness module provides a single source of truth across airworthiness directives, service bulletins, engineering orders, safety integrity levels, and aircraft operations tests, and an automatically maintained audit trail.

Production

This module helps you control short-term maintenance planning with greater efficiency thanks to real-time visibility of task progress. It also enables effective resource planning from hangar to individual task level. Key features include:

- KPI reports (automatically generated), such as budget vs. actual labour expended, defects raised, and materials issued or returned.

- Bar-coded work cards

- Reliable capture of work-in-progress data

- Fast, efficient analysis of task status

Line Maintenance

Looking for a powerful way to control short term maintenance and the related materials? Look no further than the OASES Line Maintenance module.

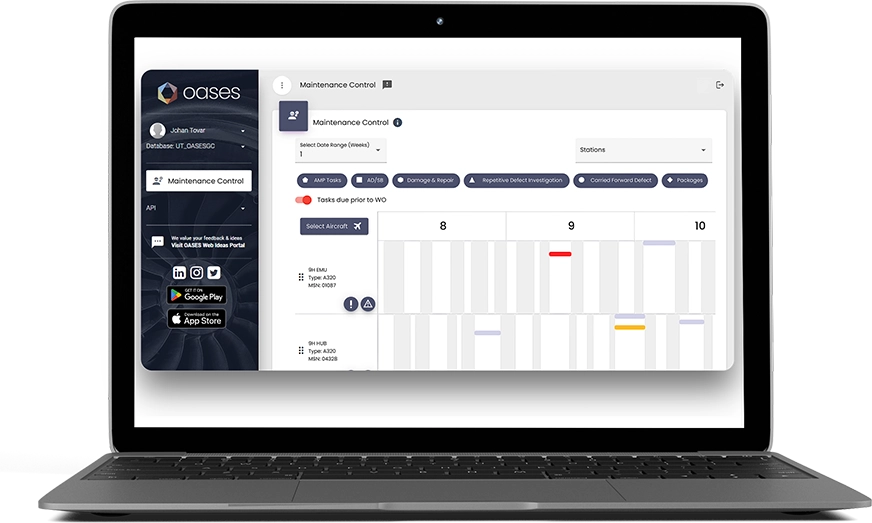

Through the maintenance dashboard, you can view the real-time status of any aircraft, fleet or base. You can also view an aircraft’s location, hours, cycles, short term maintenance requirements, and upcoming night-stop locations.

Other highlights:

- Maintenance planners and managers can forecast all scheduled activities, component removals and defect rectifications – on a single screen.

- Flexible data filtering options

- Defect histories/troubleshooting viewable by authorised users

- ‘What-if’ scenarios can be considered by calculating due times against user-defined aircraft utilisation modules.

- Integration with the Materials Management module ensures materials are available in advance of the due date.

Material Management

Always have the parts required – when you need them. The Material Management module provides full control and visibility over all your materials requirements in the most cost effective way.

Benefits include:

- Multi-location inventory management

- Automatic logging in and out of parts

- Easily create requests for quotes, send orders, and pass to accounts for payment

- Easy tracking of inventory demands and material requirements from initial creation to completion.

- Management of purchase, repair, loan and service exchange orders for aircraft parts, services, and commercial orders for non-aircraft goods and services.

- Generate all required documentation associated with inventory control

- Multiple currencies supported

- Re-ordering or stock transfer alert reports are generated when pre-defined conditions are met – along with other shortage management measures.

- Batch/serial traceability – with records automatically updated

- Loan control options

- Stock valuation – the system reports on stock values against a broad range of variables for accurate and timely reporting.

- Tool control – track the issue and receipt of tools to and from staff members. RFID tool control is also available so tools can be quickly located at any time.

OASES Cloud

OASES Cloud is what makes all of the above possible (and more – we’ll be talking about the other modules in Part 2). It’s what connects all the modules together, allowing them to communicate and share data.

With OASES Cloud, updates are delivered to your devices seamlessly so you always get the best from our solutions. Compared to an on-premise system, the Total Cost of Ownership is much less and you don’t have to worry about hardware maintenance. Other direct benefits include easy scalability and the option to access the system from anywhere in the world.

In Closing

Hopefully you have a better idea about how we turn MRO chaos into an ordered, organised process. Compliance is a walk in the park with well-managed data and flexible reporting options, and the added efficiency from using such a system reduces maintenance costs on the whole.

Join us in Part 2 to learn more about how OASES can help your organisation – and if you’d like to book a demo, contact us today.