Many industries have felt the ripple effects of global supply chain disruptions over the past few years – so much so that, in 2021, Gartner reported that 79% of large organisations would be ‘leaning into’ supply chain risk management over the following years.

With airlines constantly striving for impeccable safety standards and operational efficiency, these disruptions pose significant challenges, particularly for maintenance operations. In this article, we review the current situation and explain how airline MRO software provides the reliability you need during such times.

Aviation Supply Chain Challenges

The last few years has seen unprecedented supply chain challenges across many industries. Some of the main causes are outlined below:

- Global transportation disruptions: This has led to delays in raw material deliveries, causing production schedule problems, decreased output, and elevated costs.

- Inflation: Surging inflation has been a significant challenge for the industry, increasing the costs of materials and labour. Compounding this, capital was borrowed during the pandemic at low-interest rates (from governments and other sources); with interest rates hiking, these agreements are not so feasible anymore.

- Labour shortages: In the US and Canada in particular, there is a significant shortage in the skilled workers required to manufacture aircraft parts. This is not only due to inflation, but also the fact that many manufacturers reduced their workforce during the pandemic.

- Sanctions against Russia: Before sanctions were imposed on Russia, a great deal of the world’s titanium was sourced there, and major equipment manufacturers including Airbus and Boeing relied heavily on it. The conflict has now extended lead times for suppliers and held back plans for increasing production.

According to the Director General of the International Air Transport Association, the supply of engine parts has been particularly affected this year, which delays the delivery of new aircraft (after all, an engine contains around 23,000 parts – a shortage of just a few can slow things down considerably). Other components in short supply include semiconductors, which can have production lead times of more than three months at the best of times.

Some companies, such as United Airlines, have been upgauging for some time, using larger planes to meet demand due to airport congestion, rising costs and a shortage of pilots. Compared to 2019, the company has an additional 20 seats per departure across its network. With the delayed delivery of new aircraft, perhaps this practise will become more widespread.

Airline MRO Software: Reliability Despite Disruption

In the face of global supply chain disruptions, prioritising reliability is a must. The goal is to ensure that, despite external challenges, aircraft remain airworthy, schedules are maintained, and passenger safety is never compromised.

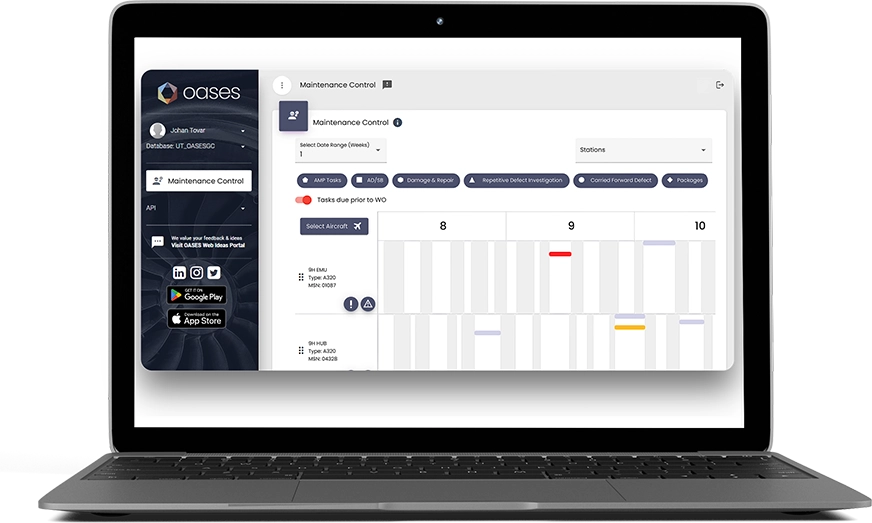

MRO software ensures that airlines are best equipped to meet these objectives by extracting value from data and providing automation.

A good MRO system should streamline every aspect of your operations, from contract modelling to maintenance planning to invoice management. This will ensure that, no matter what challenges the industry presents, you can rest assured that your maintenance teams are as efficient as possible. It will ensure that, even though the bigger picture suggests impending struggles, you retain control of the factors you can control.

With that said, there are a few aspects of MRO software worth highlighting in relation to supply chain challenges.

Aviation Inventory Management

Any MRO software should have inventory management capabilities. With OASES, users have our Materials Management module, which helps to manage orders and existing stock.

The module can manage a range of orders including purchase, repair, loan, and service exchange, and all required forms, from orders to release documentation, can be automatically generated, emailed, or printed, ensuring seamless workflow management.

As we offer cloud based solutions, users benefit from its real-time capabilities. As such, the system continuously monitors stock levels and costs, and component locations and histories are maintained to facilitate efficiency.

Also note that our modules are interconnected, providing maximum automation. For example, our Planning module generates automatic alerts for the Materials Management module, allowing parts and components to be allocated promptly.

Predictive Maintenance

Using historical data and advanced algorithms, MRO software can predict when a component is likely to fail or require maintenance. By tapping into these predictive insights, airlines and MRO providers can proactively schedule maintenance sessions, ensuring optimal aircraft uptime.

Anticipating these needs allows for more strategic procurement strategies, enabling airlines and MRO providers to order parts further in advance, thus reducing vulnerabilities associated with supply chain disruptions and minimising the impact of delayed lead times.

Our state-of-the-art solutions are designed to harness the potential of your data in this way, ensuring seamless, efficient maintenance operations.

Customs Tracking

Considering the global nature of aviation supply chains, having efficient customs management mechanisms are essential. Thankfully, the OASES Customs Tracking module offers precise tracking for both incoming and outgoing shipments, and it upholds rigorous customs compliance by maintaining thorough data tracking from the point of origin to the final goods receipt.

Whether it’s about shipments from a supplier or cross-border transactions within your own organisation, the module records the details every time goods move across a customs boundary.

Also, its intuitive dashboard delivers real-time data as soon as the shipment gets customs clearance – instead of waiting until the goods are in the warehouse.

Conclusion

Global supply chain problems are ongoing due to transportation disruptions, inflation, and worker and raw materials shortages. As a result, the aviation industry is grappling with longer lead times for critical components.

Affected organisations are forced to employ new solutions, whether that’s upgauging or embracing new technologies to keep maintenance operations consistent and timely.

MRO software acts as a beacon of reliability amidst these challenges. With its array of features, from inventory management to customs tracking tools, it ensures organisations remain resilient, efficient, and safety-compliant. The reliance on sophisticated MRO systems will undoubtedly intensify in the years to come, equipping airlines with the tools they need to navigate a future defined by uncertainties and ever-changing demands.

Airlines, MROs and CAMOs across the world are using OASES to elevate their maintenance operations. To see how your company can benefit, contact us today and book a demo.