There’s no room for compromise on safety in aviation. A significant contributor to safety is the rigorousness and standardisation of inspection and repair processes that aircraft undergo throughout their lifecycle.

A report by Deloitte states that only a few MRO companies “have an approach that enables simplification, standardization, speed and “do it right the first time” quality” and those that do are cutting total costs by 8-15%.

MRO technologies are crucial tools for ensuring that maintenance operations are conducted in line with these principles. This article takes a detailed look at how MRO software and other technologies help organisations achieve these objectives.

How Does Airline MRO Software Improve Inspection and Repair Processes?

MRO software enhances the efficiency, accuracy, and reliability of inspection and repair processes. In turn, this ensures that every aircraft is inspected rigorously and in accordance with standards. Some of the ways the software helps organisations achieve this are outlined below.

Integration with IoT Devices

Many aircraft components are now fitted with sensors that relay real-time data, offering live insights into the aircraft’s health and ensuring that any deviations from the norm are instantly flagged. MRO systems integrate with these data sources, placing the right information in front of the right personnel at the right time.

Data Management

Digital Documentation

One of the primary advantages of MRO technology is the transition from paper to digital records. Digital logs ensure that every minute detail of an aircraft’s history is stored securely, can be easily accessed by technicians anywhere, and can’t be lost or damaged as paper records might be.

Whether it’s inspection logs or records of repair procedures, there is a complete traceability of every action taken on an aircraft – crucial for safety audits and quality control. Digital records are also easier to search and reference, helping staff find information as quickly as possible.

Centralised Data Repository

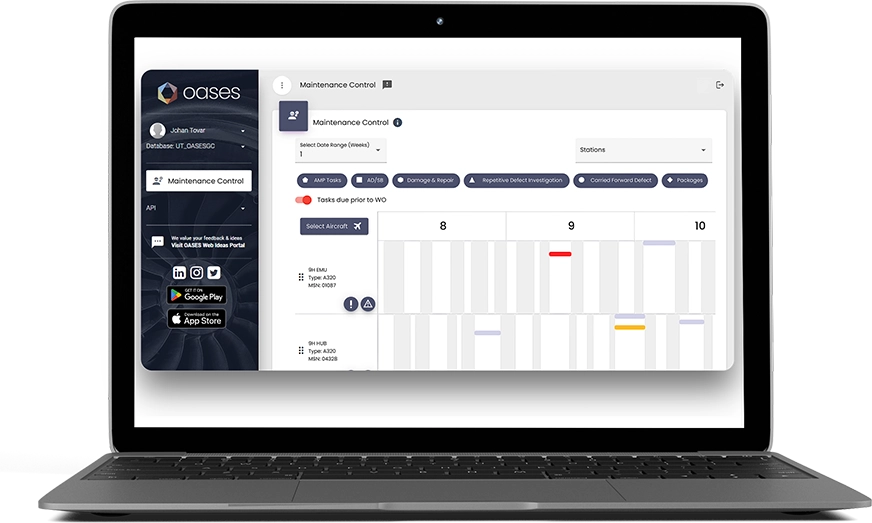

MRO software offers a single platform where all aircraft data is stored and accessed. This centralised approach ensures that inspectors, technicians, and maintenance teams have access to the same, updated information.

The OASES private cloud provides secure, worldwide access to your data, freeing you from the burden of legacy systems. However, it’s not only repair information that is stored, as OASES handles your entire MRO operation – its modules encompass inventory management, warranty management, customs tracking, and much more.

Maintenance Scheduling

Scheduled Inspections and Maintenance Tasks

MRO software can be programmed to track and notify staff of upcoming inspection intervals based on flight hours, calendar days, or other metrics. This ensures timely inspections – every time.

Predictive Maintenance with Big Data

Modern MRO platforms integrate big data analytics. Analysing historical data and drawing patterns from countless flight hours, these systems can predict when a component might fail or require attention. This foresight allows airlines to address potential issues long before they pose a threat, enhancing the protection of passengers and crew.

Automation

There are numerous ways in which MRO software can automate processes. A few examples of how OASES offers automation include:

- Automatically generating work package documentation

- Automatic compliance monitoring

- Automatic monitoring of warranty claims

- Automatic inventory management processes

- Automated invoicing processes

- Automatic reporting

With these and many other efficiency-driving features, staff can place more focus on what matters most – ensuring the airworthiness of your fleet.

Flexible Working Procedures

Mobile Compatibility and Remote Access

Modern MRO solutions are compatible with mobile devices. This allows technicians to update and access information from wherever they are working.

In addition, if a defect occurs mid-flight, data can be accessed on the ground so that technicians can be scheduled in the required location before the flight has even landed.

Task Prioritisation

Repairs can be categorised based on urgency, importance, or aircraft availability. This ensures that the most critical repairs are attended to first, minimising downtime.

Real-Time Collaboration

With real-time data accessible to all users, different teams (such as inspection, repair and parts procurement) can collaborate in real-time. This integrated approach speeds up the repair process by reducing bottlenecks, and makes it easier to address issues or questions that arise during an inspection.

Maintenance managers can also monitor the progress of repair tasks in real-time, allowing them to make informed decisions, re-prioritise tasks, or allocate additional resources if necessary. Combined with mobile accessibility, this provides the ultimate flexibility.

Integration with Other Systems

For optimal efficiency, MRO software should integrate with a range of systems within an airline’s operational infrastructure. As well as analytics and aircraft health monitoring systems, here are some other integrations to consider:

- Enterprise Resource Planning (ERP) Systems: Integration with ERP systems ensures that inventory management, procurement, financials, and human resources are coordinated with MRO tasks.

- Flight Operations Systems: Integrating with flight scheduling and operations systems allows maintenance activities to be planned around flight schedules, reducing aircraft downtime.

- Workforce Management Systems: Coordinating with these systems increases the efficiency in allocating the right technicians based on their skills and availability for specific tasks.

Task Standardisation and Compliance

By enabling standard operating procedures, MRO software ensures that repairs are conducted consistently, reducing errors and variability in the inspection and repair processes.

This ensures that all tasks are performed in accordance with regulations set by aviation authorities. Systems are also updated in accordance with changing regulations to ensure ongoing compliance.

Analytics

MRO software should integrate with analytics systems. With OASES, users can either connect with existing analytics platforms or use OASES Insights, our new BI tool. Insights helps users extract more value from their data, highlighting opportunities to improve efficiency and reduce costs.

Other New MRO Technologies

MRO software is a fundamental tool that any aviation organisation needs. But what other new technologies are making their way into the industry, improving maintenance processes and safety outcomes?

Inspection Drones and Robotics

Manual inspections take time, which makes them costly, and there is also the risk of human error. AI-powered drones using computer vision enhance the accuracy and efficiency of inspections and can provide high resolution images of components; along with 3D models, this makes diagnostics easier.

In addition, some robots can carry out basic maintenance tasks, eliminating the need for technicians to work at heights.

Augmented Reality

AR has started to make its way into MRO. Overlaying digital information on the real world allows technicians to be guided through complex repairs, and areas that need attention can be highlighted. AR also enables technicians to ‘see’ components that are hidden, without having to dismantle parts. For example, thermal imaging views can be overlaid, indicating issues such as overheating.

AR – as well as Virtual Reality (VR) – are also being used to provide interactive training experiences, allowing engineers to practise repairs in a risk-free environment.

Summary

Modern MRO technologies enhance the meticulousness of inspections and the precision of repairs. As a result, they have become indispensable assets in the aviation industry, making the skies safer for everyone.

Airline MRO software drives efficiency and standardisation, ensuring inspections and repairs are carried out in a consistent way, ensuring compliance. It also manages a huge volume of data and allows users to harness it for valuable insights. AR, drones and robotics are also promising tools that will transform the MRO landscape.

As all of these technologies continue to evolve, so too will the assurance that every flight undertaken is as safe as possible.

To see for yourself how OASES helps you establish the most rigorous yet efficient MRO operations, contact us today to book a demo.