Airlines face a myriad of challenges in ensuring the safe yet profitable and efficient operation of their fleets, and to achieve maximum aircraft reliability and minimise downtime, they must optimise their decision-making processes. Time is of the essence in this industry, so decisions need to be quick in order to maintain flight schedules.

The integration of data-driven insights tools with MRO Software has emerged as a transformative solution, helping airlines to make informed decisions, enhance productivity, and cut costs.

These tools enable operators to access real-time data and make well-informed decisions swiftly, elevating operational efficiency as well as customer satisfaction.

In this article, we explore how MRO software with data analytics is helping airlines to get maximum value from their data and rework their approach to maintenance for the ultimate cost savings.

How Business Intelligence Provides Better Foresight on Maintenance Costs

Maintenance typically makes up 10-20% of an airline’s direct operating costs and, worldwide, the annual cost of aircraft maintenance is around $40 billion. By 2025, it’s estimated that the global cost of unscheduled maintenance will reach $28.46 billion – and that’s only for a range of jets, let alone larger commercial craft. As such, it’s important to reduce any unwanted surprises when it comes to downtime.

BI brings a greater degree of certainty to otherwise unpredictable aspects of maintenance. While the time and cost requirements of new aircraft are known in advance, the same cannot be said of aircraft that have been in service for a while.

In such aircraft, maintenance requirements are less predictable, which affects scheduling as well as budgets. This applies even when it comes to everyday, routine maintenance tasks.

Without BI, the costs are discovered once the aircraft is in the hangar. This leaves no time for planning ahead. However, with BI, these costs can be predicted, helping operators to identify the actions needed in order to reduce them. At OASES, we are developing our BI tools to solve this problem.

OASES Aircraft Insights

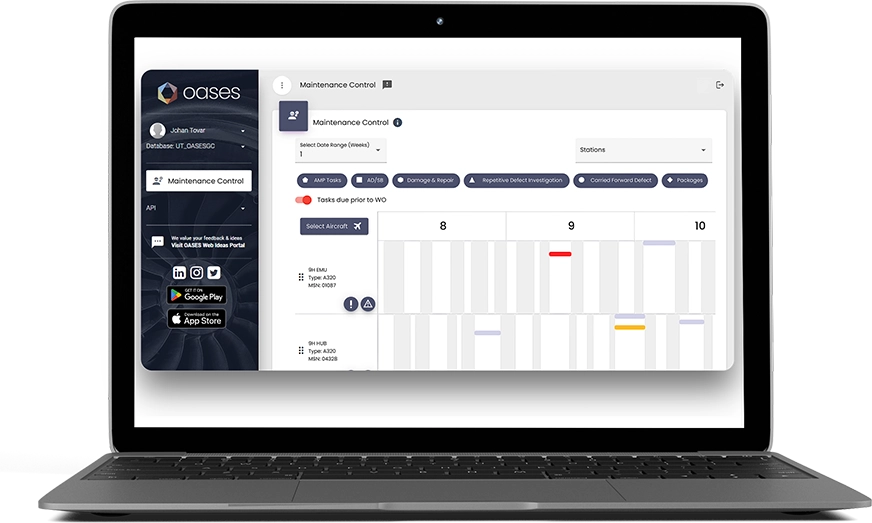

OASES Aircraft Insights is our new feature that’s designed to tackle the challenges mentioned above.

The feature uses the data collected during regular operations to build upon the OEM manual, giving personnel more helpful and comprehensive information in future. It also provides accurate timing and cost information which, in turn, will improve scheduling accuracy.

The tool provides real-time insights which are always up to date, unlike traditional reporting methods that come with a time lag.

When a work order is run, personnel can view live information via a configurable dashboard, which indicates its proven cost and time requirements.

Different personnel need access to different data, which is why we ensure that each role will have easy access to what’s relevant for them so that every member of the team can stay prepared.

If you’re already a customer of ours, Aircraft Insights uses the data you already have stored so you can get started with predicting and controlling your maintenance costs right away.

More Applications of Analytics in Aviation Maintenance

As well as the cost reduction capabilities addressed above, how else does MRO software with analytics features help cut costs and improve efficiency?

Enhancing Maintenance Scheduling with Predictive Analytics

Traditional maintenance schedules often lead to inefficiencies and unnecessary downtime. However, with predictive analytics, airlines can adopt a condition-based maintenance approach by continuously monitoring aircraft health and analysing real-time data.

The software can predict when specific components might require maintenance, allowing for proactive scheduling of maintenance tasks. This approach extends the lifespan of critical aircraft components and optimises resource allocation, resulting in significant cost savings – especially when combined with inspection drones and repair robots.

An added benefit of predictive maintenance is better fuel efficiency. This comes about through the early detection of leaky valves and other issues that cause fuel to be wasted. Over time and across the fleet, the cost savings add up significantly.

Improving Inventory Management

Vast inventories must be managed to ensure swift and efficient repairs. However, how does one strike the balance between avoiding excessive stock levels and incurring costs, while ensuring adequate parts are available so that delays are avoided?

Analytics software offers a solution to this complex challenge. It analyses historical maintenance data including usage patterns and supply chain information, and recommends optimal stock levels and forecasts demand accurately.

As a result, airlines can reduce carrying costs, avoid stockouts, and streamline their inventory management, leading to improved efficiency and reduced overheads.

Again, predictive maintenance ties in here as it informs ahead of time whether a part is likely to be required. Instead of having to have a large number of spares available just in case, predictive analytics provides the foresight for a more finetuned approach.

Optimising Resource Allocation

Effective resource allocation is vital for airline MRO operations. With analytics, airlines can optimise resource allocation, ensuring that the right personnel, tools, and equipment are deployed at the right time and place.

Advanced software solutions can consider factors like workforce availability, skillsets, and aircraft schedules to allocate resources efficiently. This optimisation not only maximises the productivity of maintenance teams but also reduces idle time and associated costs, leading to more cost-effective MRO operations.

Enhancing Compliance

Analytics can be used to monitor and track compliance with airworthiness directives and other regulatory requirements. The software can identify patterns that may indicate potential safety risks, enabling airlines to take corrective actions promptly. It can also be used to monitor fuel consumption and identify opportunities for fuel efficiency improvements and emissions reduction, helping airlines to comply with environmental regulations.

Conclusion

Business Intelligence empowers airlines to reduce maintenance costs by giving the gift of foresight – foresight about the unpredictable costs that come with maintaining aircraft that have been in service for a while. As a result, the required action can be taken to reduce costs and reduce disruption to schedules.

Analytics helps with many other decision-making processes in MRO operations. It enhances maintenance scheduling, streamlines resource allocation, helps ensure compliance, and improves inventory management.

The OASES team are excited to offer the Airline Insights tool, which takes our software to new heights in terms of helping our customers reduce costs. It gives airlines and MROs a new handle on their vast volumes of data, ensuring they are always making the most optimal decisions – in real-time.

To see OASES in action, contact us today to book a demo.