The effect of climate change on MRO operations is two-pronged: responding to changing maintenance requirements, and introducing more sustainable maintenance practises.

Changes in temperatures, precipitation, and other weather phenomena affect aviation operations across the board. However, this article examines how MRO operations in particular may be affected, and the measures being taken to ensure safety and minimise disruptions in the years to come.

How Does Climate Change Affect Aviation Maintenance?

The aviation industry is highly sensitive to changes in weather patterns and extreme weather events, which are expected to increase in frequency and intensity in some regions.

Several of the most relevant changes that will affect aviation maintenance are higher temperatures, increased precipitation, changing wind patterns, and storms that are more frequent and/or more powerful.

Other factors, such as rising sea levels, will disrupt operations at airports in coastal locations.

High and Extreme Temperatures

High and extreme temperatures cause stress to engines. As well as the increased risk of EGT overlimit events, the increased fuel requirements for taking off in hotter temperatures causes engines to wear out faster.

In the long run, engine designs will need to adapt to such conditions while in the short-term, more frequent inspections will be necessary. Take-off weight restrictions may also need adjusting due to the effect of decreased air density on lift.

Extreme temperatures will cause stress to cooling systems and there may be an increased demand for such systems.

Finally, checks may need to be carried out inside facilities if temperatures render it unreasonable for maintenance teams to perform checks outside.

Changes in Precipitation Levels

Both increases and decreases in precipitation will affect maintenance operations. De-icing costs will increase in some areas – and with increased de-icing comes increased fan blade erosion and increased run-off, potentially causing contamination.

Managing the risk of in-flight icing is going to be a priority. Since not all aircraft are approved for flying in icing conditions, disruption may be expected in this regard, while existing ice protection systems may also need to advance.

As for droughts, any water-intensive activities may have to be restricted in the affected regions.

Changes to Wind Patterns

Changes in atmospheric circulation can cause increased turbulence in certain regions, putting further stress on aircraft and leading to increased wear and tear. In addition, wind-driven particles such as sand or dust can become more prevalent, increasing the risk of corrosion on aircraft surfaces and components.

More frequent inspections and maintenance may be required and corrosion prevention measures may need to improve.

Changes to the logistics of MRO operations might be necessary if flights must be re-routed. Changing flight schedules means changing maintenance schedules; therefore, operators will need to use a robust system in order to manage fleets with agility.

Increased Storms

An increase in the frequency and intensity of storms, including extreme events such as hurricanes and typhoons, will require further adaptation. Again, severe winds, hail, and heavy precipitation associated with these events can damage aircraft surfaces and other components. Maintenance activities, such as inspections for hail damage or water ingress, may need to be intensified following extreme events.

There will also be the added cost of repairs due to lightning. Lightning strikes over the U.S. are predicted to increase by 50% during this century and, as it stands, strikes to commercial U.S. aircraft already cost $2 billion per year collectively in operating costs and passenger delays.

The Effects of Sustainable Fuels on Aircraft Maintenance

Airlines have been exploring sustainable fuels for some time. However, they bring their own issues to the table relating to engine maintenance. For example, the use of bio-diesel in marine engines has led to early failure, while in automotive engines, it can cause oxidisation of the tank, among other undesirable consequences.

More research and experimentation is needed in order to understand the long-term effects of using such fuels for aviation.

How is Aircraft Maintenance Adapting to Climate Change?

Regulatory Frameworks and Partnerships

Regulatory framework plays a crucial role in promoting climate change adaptation in aircraft maintenance. The International Civil Aviation Organization (ICAO) and the United Nations Framework Convention on Climate Change (UNFCCC) have both developed policies and guidelines to promote sustainable aviation and reduce the environmental impact of air travel.

Airlines, aircraft manufacturers, maintenance providers, and regulatory bodies must continue working together to develop and implement adaptation strategies. Some existing projects include The Sustainable Aviation Fuel Users Group (SAFUG), a collaboration of airlines and manufacturers that aims to promote the use of sustainable aviation fuels.

New Maintenance Schedules

Schedules must be adjusted to account for the increased maintenance requirements. As a result, strategies such as predictive maintenance will become more important than ever; not only will it help keep stressed components in top condition, but it will also help to offset the cost caused by more frequent inspections and repairs.

Regular maintenance checks can also ensure that engines are operating efficiently, minimising fuel consumption and emissions (or helping to offset the increased use of fuel caused by operating in higher temperatures).

New Technologies

The industry is continuously exploring new technologies to improve aircraft maintenance. One example is the use of drones and robotics for inspections and repairs, which will also offset the cost of increased maintenance requirements, reducing the need for on-site personnel. Drones can inspect components in hard-to-reach areas, such as the top of the aircraft fuselage, improving accuracy as well as safety.

Currently, robots can perform routine maintenance tasks such as cleaning and painting, but who knows when they will be able to perform more complex maintenance jobs? For now, they free up technicians’ time so they can focus on such tasks.

New Aircraft Designs

One of the most significant strategies to adapt to climate change is the development of new aircraft designs that are more resilient to extreme weather events. For example, Boeing’s 787 Dreamliner features a lightweight carbon fibre composite structure that is more resistant to corrosion. It’s also very fuel-efficient.

In addition, NASA and Boeing’s notable collaboration seeks to develop next generation craft designed to reduce emissions.

Sustainable Materials and Recycling

The use of sustainable materials in aircraft manufacture is another important step for reducing the environmental impact of the industry, even though it’ still in its infancy. Airlines will also need to maximise their recycling efforts.

Conclusion

Climate change adaptation in MRO is crucial for the safety and reliability of air travel. The industry must continue to innovate and find new ways to adapt while minimising the impact of air travel on the environment.

The adoption of emerging technologies such as drones and robotics will play a significant role in improving the efficiency of maintenance activities, and advanced analytics will ensure maximum value is derived from aircraft data, helping to predict and manage maintenance with new levels of precision.

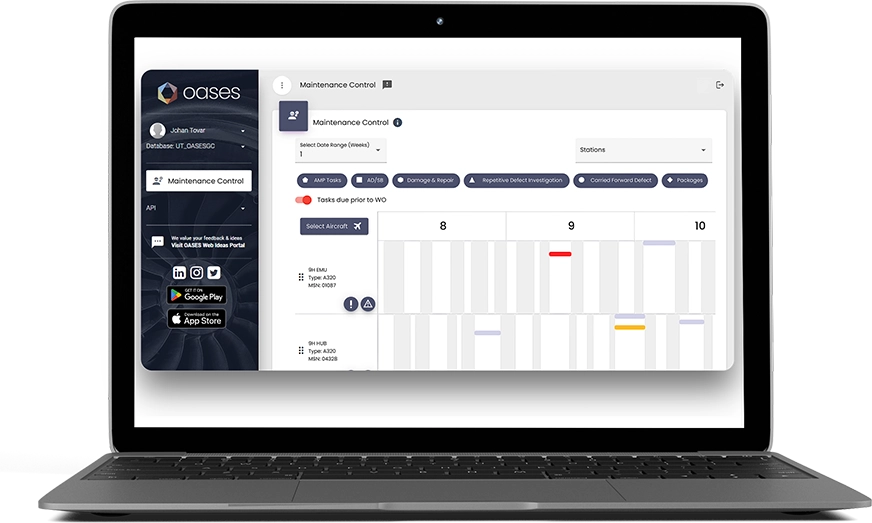

To discover how OASES can bring more stability and efficiency to your MRO operations in the uncertain times ahead, contact us today to book a demo.

To learn more or book an OASES demo, contact us today

For organisations looking to ascend to new heights of operational excellence, contact us today to book a demo.