The routine checks, servicing, and minor repairs performed during line maintenance is essential for ensuring an aircraft’s airworthiness during its stay at a given airport.

Orchestrating such activities can be challenging for many reasons, but airlines, MROs and CAMOs must find a way to overcome such obstacles. Doing so minimises disruptions to flight schedules and enhances customer satisfaction.

In this article, we look at some of the pain points organisations experience every day when it comes to line maintenance – and how OASES tackles them.

Line Maintenance Challenges

Time Constraints

Short turnaround times between flights leave little margin for error in completing necessary maintenance tasks, inspections, and repairs. Line maintenance crews must ensure that all safety-critical systems, components, and equipment are in proper working order while working under pressure.

Flexibility

MROs in particular need to be flexible. When schedule changes or delays occur, airlines will not always provide much notice. Regardless, organisations need to be ready to adapt (within reason). This means having solid processes in place to ensure customers are served adequately and that safety is maintained according to strict deadlines.

Despite the fact that line maintenance tasks are usually minor, unforeseen circumstances can occur that require engineers to resolve other defects. Organisations must be prepared for this, which means managing more resources than people i.e., the right parts need to be in the right place at the right time.

Parts Availability

Delays in acquiring necessary parts can lead to aircraft being grounded, which impacts flight schedules and customer satisfaction. Currently, this is more difficult due to supply chain shortages.

In addition, not all line stations store parts, which means maintenance teams have to source parts quickly in AOG scenarios.

Resource Allocation

Allocating maintenance resources (including staff, tools, and equipment) to different aircraft in a fleet is a complex task. The skilled labour shortages the industry is facing at the moment exacerbates the challenge.

According to a survey by Oliver Wyman, the lack of skilled workers is among the top three challenges in MRO today. In the worst case scenario, demand will outstrip supply by 26% in 2032. The best case scenario predicted is that supply will outstrip demand by 21%. One potential strategy to encourage Gen Z to be interested in the profession is to use more advanced technologies such as Virtual Reality and drones.

Compliance

Ensuring compliance with strict aviation regulations and safety standards is critical but can be complex and time-consuming. Accurate record-keeping is essential, yet managing vast amounts of data and ensuring its accuracy is a challenge. Keeping up with changing regulations is another hurdle.

Aging Fleet

Aging aircraft may require more frequent maintenance, repairs, and parts replacement. Balancing the maintenance needs of older and newer aircraft in a fleet can be a logistical challenge.

Environmental Factors

Factors such as extreme weather can affect line maintenance operations; for example, adverse condition may limit access to the aircraft or require special precautions during tasks. In some cases, hangars may be needed, pushing up the cost of maintenance and giving personnel more admin. Such factors can affect scheduling, so effective contingency planning is a must.

Communication and Collaboration

Effective collaboration among maintenance crews, flight crews, ground personnel, and maintenance control centres is crucial. Miscommunication or delays in relaying maintenance issues can impact operational efficiency – and one common cause behind it is poor data management.

Cost Control

Managing maintenance costs is a constant concern. Climate change and increasing passenger numbers are both significant factors that will increase MRO spending. In fact, global spending on MRO is forecast to reach UD 139 billion by 2033, up from USD 112 billion in 2023 – an annual growth of 2%.

Some specific costs include:

- Labour: Due to the need for skilled technicians who can work quickly and efficiently to minimise turnaround time, labour costs are significant – and they’re increasing.

- Equipment: The costs associated with equipment such as ground power units, air start units, and test equipment can add up quickly, especially if the airline operates a large fleet.

- Consumables: The cost of consumables such as filters, oils, and other materials, which must be regularly replenished.

- Training: Technicians must be trained on the various aircraft types and maintenance procedures used by each airline.

Balancing safety and compliance with cost-effective maintenance practices requires diligent planning, especially considering recent increases in materials costs.

How OASES Streamlines and Automates Line Maintenance

Through OASES’ Line Maintenance module – and the other modules it integrates with – we provide a comprehensive solution to these challenges. The system’s capabilities are vast, helping organisations to seamlessly coordinate and execute all tasks.

Short Term Planning and Forecasting

Short-term planning and forecasting are crucial for completing line maintenance on time while adhering to safety standards. OASES supports this process by allowing planners and managers to forecast all short-term scheduled activities, including component removals and defect rectifications, on a single screen. They can also visualise the knock-on effect of short notice schedule changes, enabling them to respond optimally.

Automated LMC Worksheet

OASES automates the generation and emailing of LMC worksheets, detailing all maintenance and rectification activities to be performed at the appropriate station. This ensures that maintenance teams are well-informed about the tasks ahead, facilitating better preparation and execution of activities, helping to reduce turnaround times.

Defect Histories and Troubleshooting

Access to comprehensive defect histories enables maintenance teams to quickly identify and address recurring issues. OASES provides an extensive database that allows users to filter defect information by various criteria such as ATA system, CFD category, and date range. This access supports effective troubleshooting and problem resolution.

Integration with OASES Materials Module

By integrating key processes from other technical areas such as planning and materials management, OASES rationalises the workflow of Line Maintenance Control.

Let’s consider materials management as an example. This integration ensures that materials and parts are acquired well ahead of the due date. When requirements are created, the system automatically routes them depending on the user’s specific rules. Rules include conditions such as:

- If stock is available, reserve it automatically.

- If stock is required immediately, send a picking notification to the relevant warehouse.

- If stock is not available or the value of the request exceeds pre-set limits, the system can automatically email the manager or buyer to let them know about the requirement. (The user that initiated the request can access information on the actions taken by the manager/buyer, including the current status and expected delivery.)

Electronic Data Integration

Our MRO software excels in electronic data integration, offering a flexible framework for the export and import of data in real-time. This allows for seamless communication between OASES and external systems such as EFB, ETL, and e-enabled aircraft, supporting various data formats like web services, XML, and CSV.

The system’s ability to handle data efficiently reduces the opportunity for errors caused by duplicated data entry (due to manual processes), thus enhancing overall accuracy.

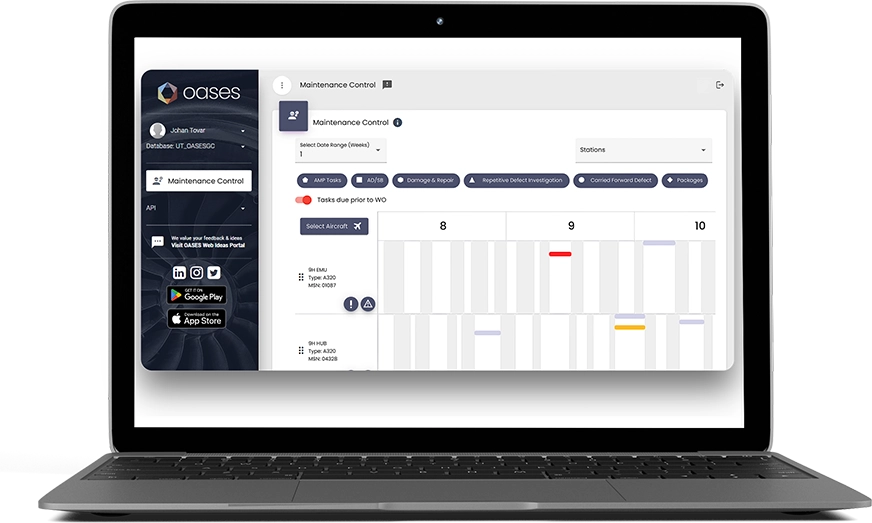

Real-Time Dashboard

Real-time dashboards are game changer for maintenance control teams. They offers visibility into the status of any aircraft, fleet, or base, displaying CFD/ADDs in real-time alongside aircraft location, hours, cycles, and short-term maintenance requirements.

This high level of visibility allows maintenance teams to make informed decisions quickly, ensuring that aircraft downtime is minimised and that the fleet operates efficiently and safely.

Documentation and Compliance

Poor documentation can significantly slow down maintenance processes and complicate compliance. OASES solves this problem by maintaining electronic records of maintenance activities, including defect reporting and rectification actions, allowing for easy audit and review.

Conclusion

OASES offers a robust solution to the complex challenges of line maintenance. Through its comprehensive suite of tools for planning, forecasting, real-time monitoring, and materials management, it simplifies processes and ensures that aircraft utilisation is maximised, thus improving profit margins.

For improved efficiency, safety, and operational readiness, complete the form below to book a demo.